Nya Wermlands-Tidningen (NWT) printing house locates at Karlstad, Sweden. It has more than 180 years history as a newspaper publisher and printer. The first issue of newspaper was published on January 4th 1837.

NWT is currently one of Sweden´s largest local newspaper with coverage of news and distribution in the midland areas of Sweden.

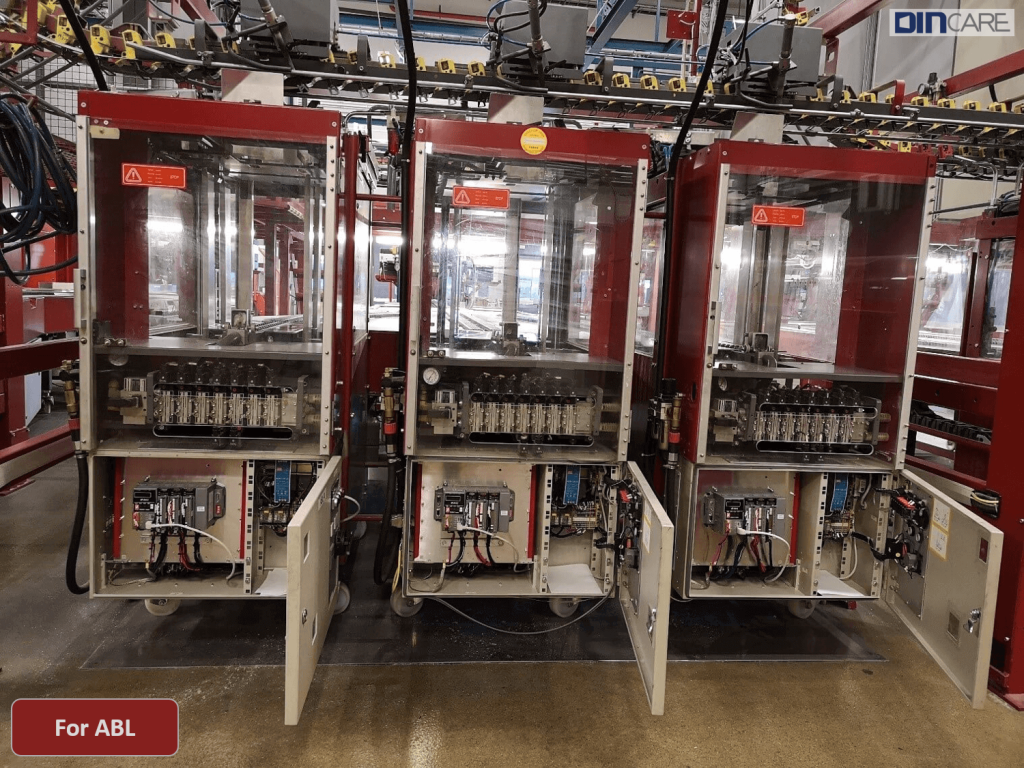

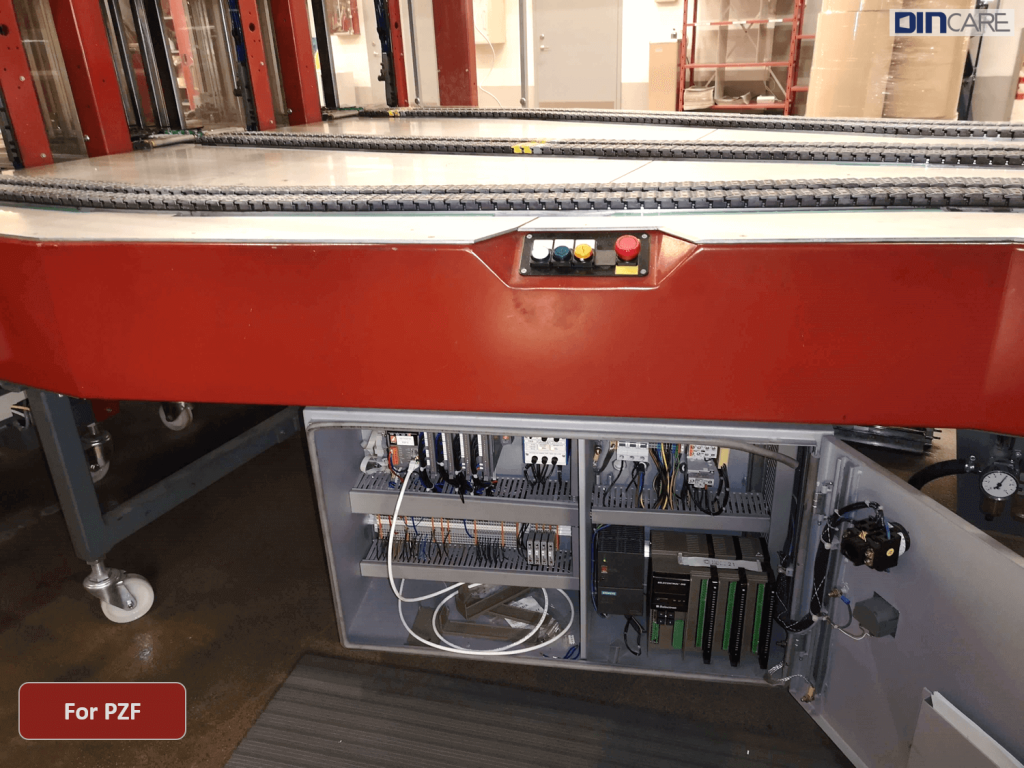

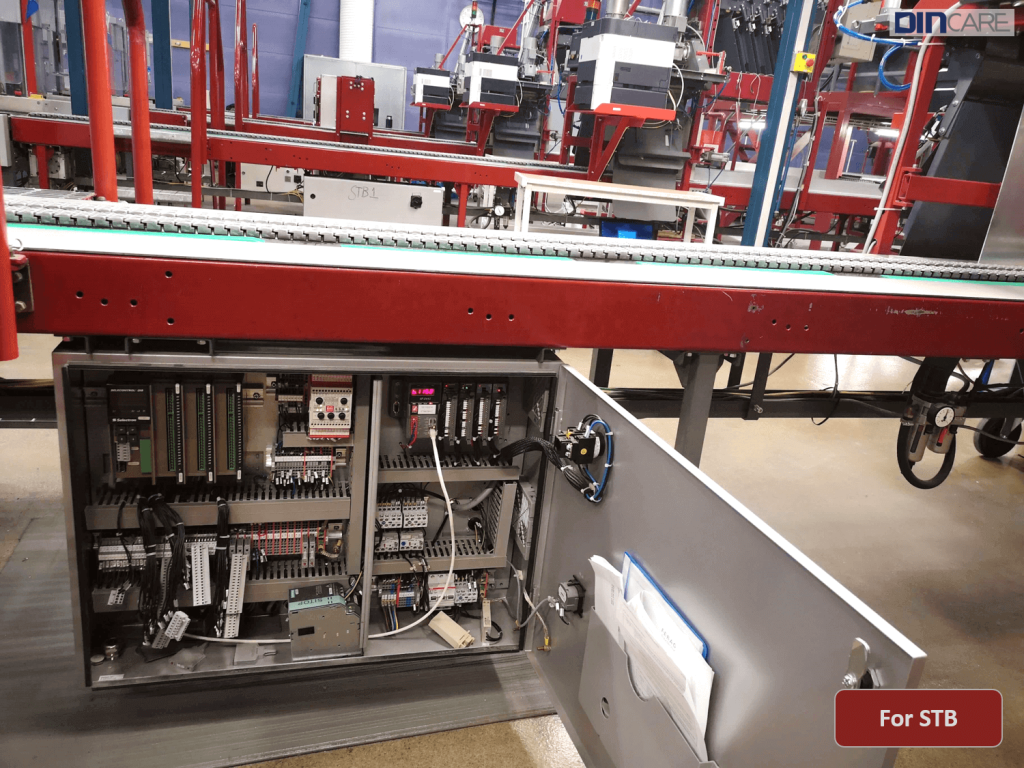

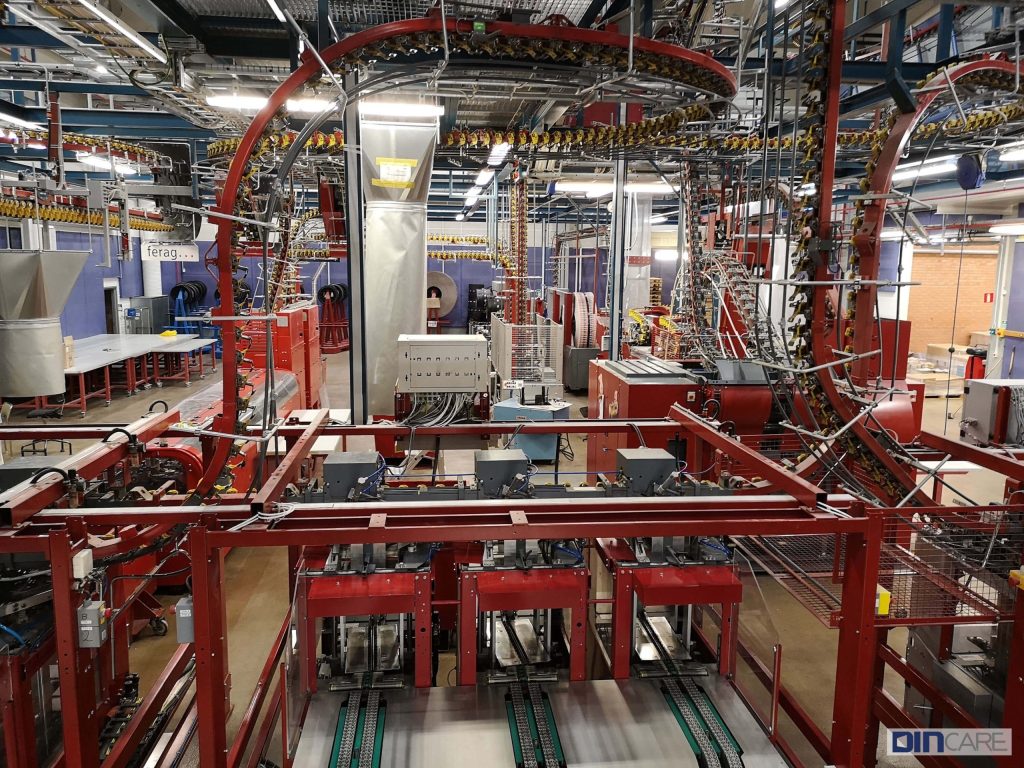

NWT's mailroom was supplied by Ferag and installed since 20 years ago. The mailroom consists of 3 Ferag TTR conveyor lines, with 1 MTS line for quarter fold, and 4 ABL groups for Tabloid. Each ABL group has 3 ABL stackers, 1 PZF bundle merger, 1 STB, 2 DBHs, and 2 printers. The bundle loading system was supplied by Ferag PKT with 6 pushers. Most of these machines are still in good operation. But the hardware components, particularly control electronics for Ferag bitbus systems are no longer available in the market. There are no more spare parts for the control system if something goes wrong, which can not secure the daily production for a long time.

By fully understanding the situation and challenges of the mailroom control system, DinCare has been working closely with NWT since the summer of 2018. During the cooperation, DinCare has figured out the best solution for NWT. After some months, DinCare has successfully developed and deployed the first solution over the world to replace all the Ferag mailroom bitbus control systems for 2xALS, 12xABL, 4xPZF, 4xSTB and 8xDBH with the modern DinCare Ethernet based PAC controlling system (DEPACS).

All printronix line matrix printers have been replaced by laser printers to save paper cost and maintenance cost for NWT. The outdated DBH computers have been also removed, since there is no need of DBH computers any more in our new system, which greatly simplifies the maintenance work for DBH and topsheet printing.

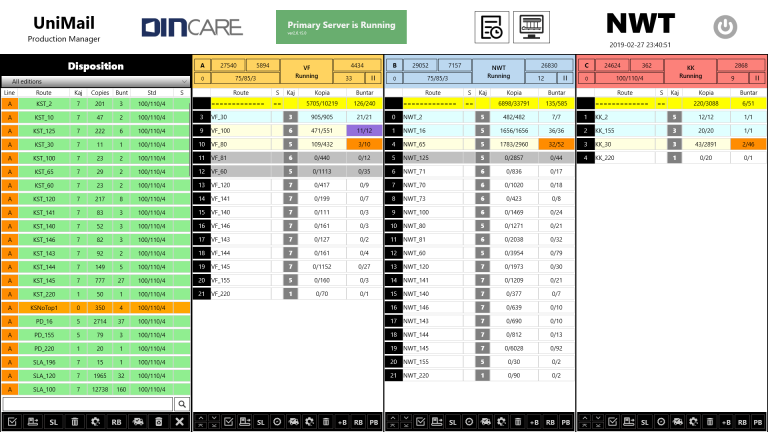

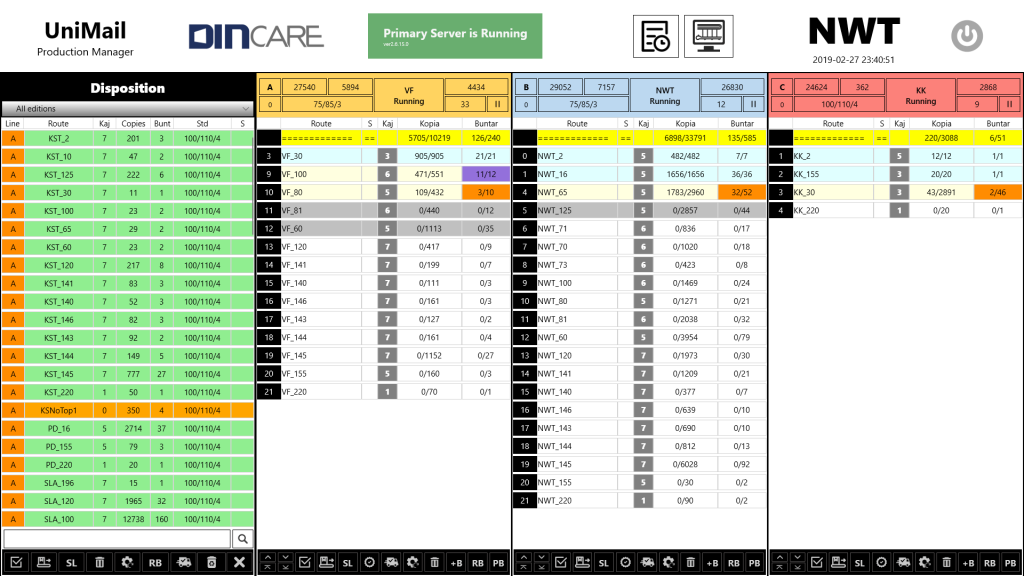

Last but not least, we have also developed the latest user interface to manage the production in a more efficient and user-friendly way, which gives a lot of benefits to operators. In return, we build strong trust from operators and managers.

Nya Wermlands-Tidningen (NWT) printing house locates at Karlstad, Sweden. It has more than 180 years history as a newspaper publisher and printer. The first issue of newspaper was published on January 4th 1837.

NWT is currently one of Sweden´s largest local newspaper with coverage of news and distribution in the midland areas of Sweden.

NWT's mailroom was supplied by Ferag and installed since 20 years ago. The mailroom consists of 3 Ferag TTR conveyor lines, with 1 MTS line for quarter fold, and 4 ABL groups for Tabloid. Each ABL group has 3 ABL stackers, 1 PZF bundle merger, 1 STB, 2 DBHs, and 2 printers. The bundle loading system was supplied by Ferag PKT with 6 pushers. Most of these machines are still in good operation. But the hardware components, particularly control electronics for Ferag bitbus systems are no longer available in the market. There are no more spare parts for the control system if something goes wrong, which can not secure the daily production for a long time.

By fully understanding the situation and challenges of the mailroom control system, DinCare has been working closely with NWT since the summer of 2018. During the cooperation, DinCare has figured out the best solution for NWT. After some months, DinCare has successfully developed and deployed the first solution over the world to replace all the Ferag mailroom bitbus control systems for 2xALS, 12xABL, 4xPZF, 4xSTB and 8xDBH with the modern DinCare Ethernet based PAC controlling system (DEPACS).

All printronix line matrix printers have been replaced by laser printers to save paper cost and maintenance cost for NWT. The outdated DBH computers have been also removed, since there is no need of DBH computers any more in our new system, which greatly simplifies the maintenance work for DBH and topsheet printing.

Last but not least, we have also developed the latest user interface to manage the production in a more efficient and user-friendly way, which gives a lot of benefits to operators. In return, we build strong trust from operators and managers.